PM310 Track Undercarriage

The PM310 is an efficient, highly maneuverable milling machine with a cutting width of 1000 mm (39.4 in) that performs controlled full-depth removal of asphalt and concrete pavements in a single pass.

Efficient Performance

- Cat® C9.3 engine meets regional emission standards

- Smooth and efficient operation with Automatic Idle Control and multiple rotor speeds optimize output and demand on the engine

- High capacity cooling system keeps engine at ideal temperatures for optimal fuel efficiency and lower emissions

- Automatic load sensing on the rotor adjusts milling speed to prevent stalls and optimize production

Maneuverability and Control

- Robust propel system features dual displacement planetary motors at each leg post, utilizing a cross-drive pattern for additional traction in straight cuts

- Automatic traction control maintains consistent speed in the most challenging applications

- Articulating right rear leg maximizes stability and traction in demanding cuts while enhancing flush cutting capability when needed

- Optional ballast weight kit available to increase productivity in specific applications

- Wheel or track undercarriage options offer a balance of traction, speed and maneuverability

- Reliable track undercarriage option leverages proven designs from Cat dozers and an automatic tensioning system to ensure consistent performance and longer track life

- Ability to electronically switch between rotor speeds during operation

Comfortable Work Environment

- Operate in comfort with a standard suspension seat, adjustable right arm console and intuitive, ergonomic controls

- A sliding operator station extends up to 215 mm (8.5 in) to provide improved visibility to the cutting edge

- Work day or night with backlit keypads and well-lit work areas

- Touchscreen displays provide access to gauge cluster, operating information, remote camera feeds, machine controls and diagnostics

- Optional remote cameras enhance visibility to the cutting edges, conveyor, and rear of the machine

- Cut closer to obstacles on the right side using an optional remote camera above the cutter box with an adjustable on-screen guidance line

- Optional windscreens can be added for increased comfort

- Maximize dust removal from the working areas with the optional dust abatement system

Durable Cutting System

- The rotor drive system features a heavy-duty dry clutch, dual stage belt drive and automatic belt-tensioning to prevent slippage

- Reinforced cutting chamber offers enhanced durability

- Hardened full length side plate skis and anti-slab shoes reduce wear and maintenance

Boost Precision with Integrated Cat Technology

- Achieve accurate, repeatable and automatic cutting precision with the integrated Cat GRADE with Grade and Slope system

- The optional grade control box can be positioned in the operator station or on the back of the machine to enable interaction with the grade system from the ground level

- Obtain full control of grade and slope from any control box

- Seamlessly switch between multiple grade sensors for uninterrupted accuracy during milling

- Adjust the speed at which the rotor drops into the cut for optimal machine control

- Set and automate transitions in/out of cuts and save settings for future jobs

- Clear obstacles in the cutting path with ease using the obstacle jump feature

- Enhance for full 3D milling operation (additional hardware required)

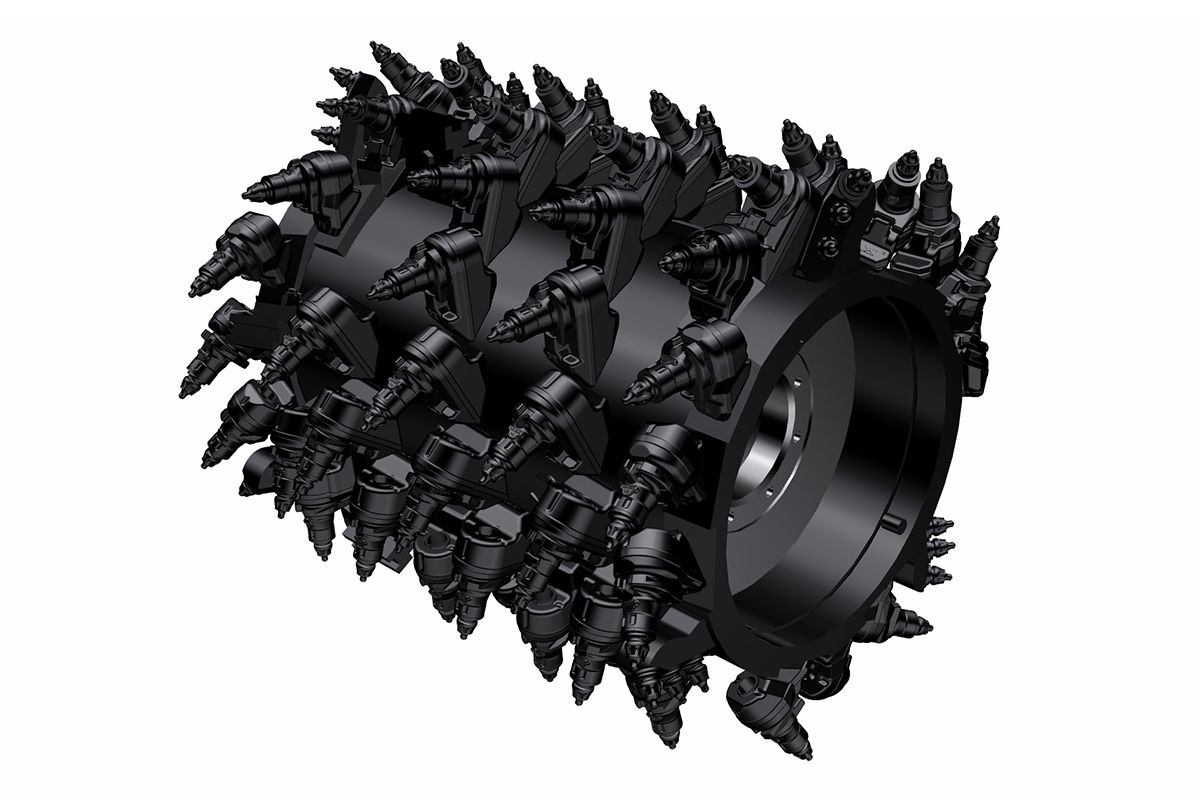

System K Rotors

- Cat System K rotors feature efficient material flow with an excellent cutting pattern for numerous applications

- A tapered dual-retention design secures toolholders in place without a retaining pin, bolt or setscrew, speeding up replacement and eliminating the need for fasteners or torqueing

- Reversible paddles and high strength alloys reduce wear and abrasion to extend rotor life

- Optional diamond bits can extend replacement intervals up to 80 times longer than conventional carbide bits

Simplified Service

- Maintenance is easier with large service doors for access to critical components

- Maintenance-free track components and easy to replace track pads lower service costs

- Standard ground-level controls and an optional hydraulically-operated rotor turning device simplify bit removal and replacement

- Operate select machine functions during maintenance and service with the accessory drive system

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life

- Extended hydraulic oil service intervals: 3000 hours without oil sampling, 6000 hours with oil sampling

- Track scheduled maintenance with Cat Product Link™ telematics services

- Electronic Control Modules (ECMs) monitor machine systems to alert the operator of performance issues and can be paired with Product Link options to enable additional remote services with your local Cat dealer

- Multi-piece, cartridge-style engine filters are environmentally friendly, reducing waste and lowering replacement costs

- Convenient parts availability, dealer locations and service repair kits simplify ordering of high wear components